|

A.Selection of turning geometries

|

|

Geometry of Negative turning inserts:

|

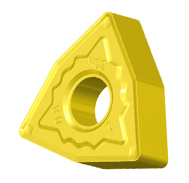

| PB2 geometry for turning steel in finishing operation |

.jpg) |

|

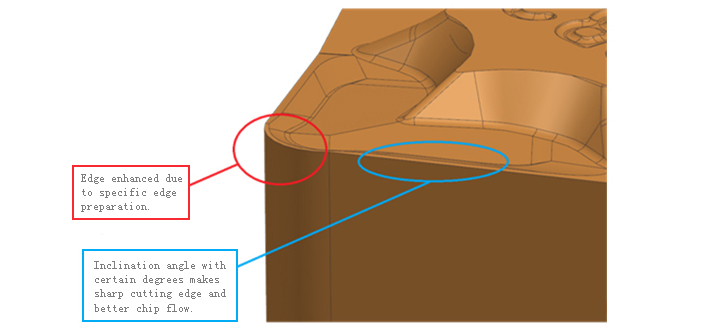

PB2 can be also used in finishing stainless steel and heat-resistance steel. With lower cutting forces, and reliable chip control, this geometry can achieve good machining precision and surface finishing.

|

| |

|

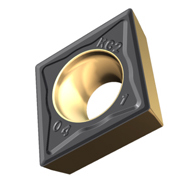

| PC3 geometry for turning steel in semi-finishing operation |

.jpg) |

|

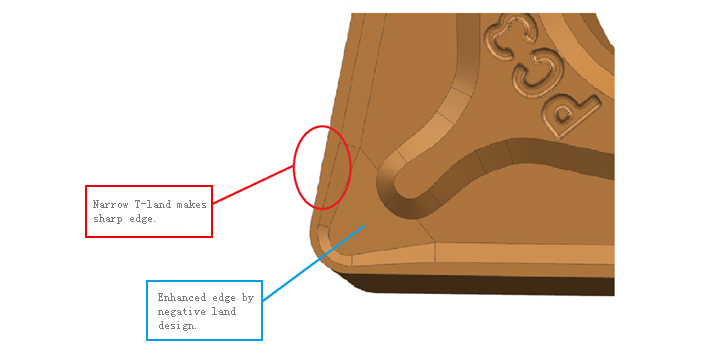

PC3 geometry can be used in machining stainless steel and cast iron material, with wide chip control range. The negative land ensures good chip control and chip flow.

|

| Character of PC2: |

|

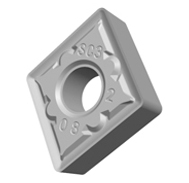

| MC2 geometry for turning stainless steel in semi-finishing |

.jpg) |

|

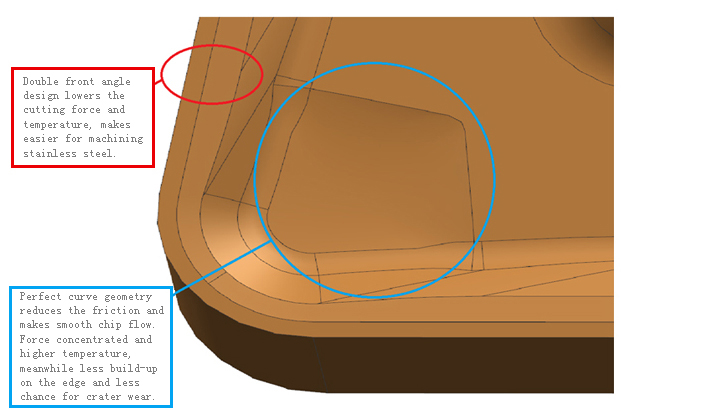

MC2 geometry also can be used semi-finishing and finishing in steel and high-temp alloy.

|

| Character of MC2: |

|

| |

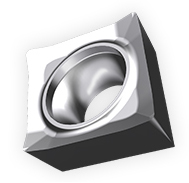

.jpg) |

|

SC3 geometry is a good solution for machining high-temp alloy. It can be applied in machining stainless steel, nickel-based, cobalt-based and titanium-based alloy. Universality inserts lower the stock and economic. This geometry has sharp edge and double front angle, resulting in good machining precision and surface finishing.

|

| KC4 geometry for turning cast iron in semi-finishing |

|

| KC4 geometry can be used semi-finishing and roughing steel and cast iron. This geometry ensures good chip control, low cutting force and excellent tool life, which results in good performance in machining steel and cast iron. |

| Geometry of positive inserts: |

| PA2 |

.jpg) |

| PA2 geometry is used for finishing of P material, which with high accuracy, very good chip control and surface finishing. |

| PC3 |

|

|

PC3 geometry is used for semi-finishing and roughing of P material, it is also used for most of other materials.

|

| MC2 |

|

|

MC2 geometry is used for finishing and semi-finishing of M materials.

|

| KC2 |

|

| KC2 geometry is used for semi-finishing and roughing of K materials. |

| SC3 |

|

| SC3 is applied to titanium alloys, nickel alloys, aluminum alloys and soft steels. |

| NC2 |

|

|

NC2 is applied to ‘N’ materials like aluminum alloys, and also it is suitable for titanium alloys, copper and brass. NC2 has large positive rake angle, sharp edge and good surface finish.

|